24-hour customer service hotline:

0086+400-800-8605

+86176-1673-8512

Reservation:

+86-0536-7519229

The competition in the cement industry is very fierce, but the key is the competition in manufacturing costs. The main power consumption equipment includes crusher, ball mill and fan, which account for more than 98% of the total power consumption of the cement plant, of which the fan accounts for about 20% of the total energy consumption, and the installed capacity of the fan accounts for 30-35% of the total installed capacity of the cement plant. Therefore, it is extremely important to improve the operation efficiency of the fan and do a good job in reducing consumption and increasing efficiency of the fan.

At present, roots blower used in cement plant has high energy consumption, low efficiency, large vibration, large noise and high maintenance cost. Magnetic levitation blower is a high-efficiency, energy-saving and environmental protection product that is integrated with active magnetic levitation bearing technology and high-speed permanent magnet synchronous motor technology. It adopts an intelligent control system. Compared with the traditional roots blower, it saves 30-40% energy and reduces noise from 120dB to 80dB. It has no friction, no contact, no lubrication, zero transmission loss, and a service life of more than 20 years. Magnetic levitation blower can replace roots blower used in cement plant at present, and can be mainly used for kiln head, pulverized coal conveying of decomposition furnace, primary air fan at kiln head, raw material / cement silo bottom homogenization, etc. it is estimated that 1.5 kwh of electricity can be saved for 1 ton of cement after replacement.

Appearance drawing of magnetic suspension blower

At present, there are four types of fans on the market: Roots blower, centrifugal blower, air suspension blower and magnetic suspension centrifugal blower. The performance of these fans is compared by the small editor as follows:

Main advantages of maglev centrifugal blower:

energy conservation

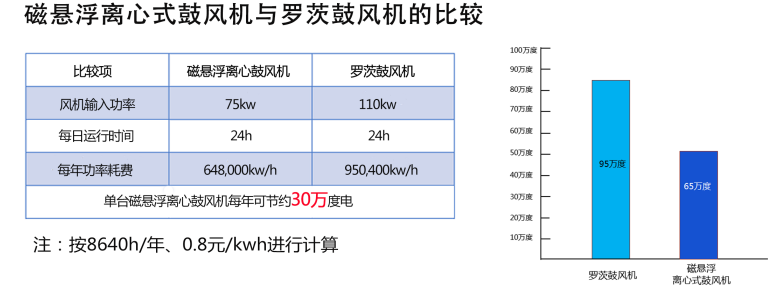

Compared with roots blower, the efficiency of maglev centrifugal blower is increased by more than 30%. Taking the 100kW magnetic suspension centrifugal blower as an example, compared with the roots blower, it can save more than 300000 kwh of electricity and more than 200000 yuan of electricity.

Environmental protection advantages

• no lubrication is required, and the delivered air is clean and pollution-free.

• magnetic bearings are completely friction free, with low operating noise as low as 80 dB, reducing the occurrence of occupational diseases and improving the working environment of workers.

• calculated by 100kW magnetic levitation centrifugal blower, each blower can reduce about 275 tons of CO2 emissions per year.

Low operating costs

• the magnetic bearing is completely friction free, reducing the probability of product damage, and the service life of the fan can reach more than 20 years.

• simple maintenance, just replace the filter regularly.

• no lubrication system is required, which saves the cost of lubricating oil and cleaning.

• the motor is driven by direct connection, with small volume, light weight and space saving.

• domestic production can ensure the timely supply of spare parts.

Shandong Tianrui Heavy Industry Co., Ltd. is a high-tech enterprise engaged in the research and development of magnetic levitation technology. After 6 years of research and development and market promotion, Tianrui heavy industry's magnetic levitation blower has been rapidly applied in many industries such as cement, urban sewage treatment, papermaking, chemical industry and pharmaceutical industry, providing high-quality solutions for customers' upgrading and transformation, and has been highly recognized by users. According to the evaluation of China high tech Industrialization Research Association, the overall performance and energy-saving and noise reduction technology of maglev centrifugal blower have reached the international advanced level. The "one circle and one belt" fund of Shandong Development Investment Holding Group Co., Ltd. has invested in the magnetic levitation centrifugal blower industry of Tianrui heavy industry, which will provide strong capital and policy support for promoting the development of the emerging magnetic levitation industry.

Shandong Tianrui Heavy Industry Co., Ltd. is a national manufacturing industry single champion of the Ministry of industry and information technology, a gazelle enterprise of the national high tech Zone, an invisible champion enterprise of Shandong Province, an intellectual property brand unit of 100 key core technologies in Shandong Province, and a national intellectual property advantage enterprise. The company has strong scientific and technological innovation strength, with five provincial innovation platforms including Shandong Engineering Technology Research Center, Shandong Engineering Laboratory and Shandong enterprise technology center; Li Yongsheng, chairman of the board of directors of the company, is an expert enjoying special allowance of the State Council, a leading talent of the national "ten thousand talents plan", a leading talent of Taishan industry in Shandong Province, and a think tank expert in Shandong Province. The company has 157 authorized patents and 3 Shandong famous brand products; It won 12 provincial and ministerial level science and technology awards, national advanced quality and efficiency enterprise, Weifang mayor quality award and other honors.

At present, energy saving and emission reduction are the primary issues faced by the cement industry. Energy saving of fans is of great significance to reduce the cost of cement and improve the competitiveness of enterprises. With the continuous emergence of new technologies, the energy-saving transformation of fans in various cement plants has become an inevitable trend. Shandong Tianrui Heavy Industry Co., Ltd. will adhere to the tenet of excellence, professional focus, exceeding expectations and creating success, become the technical leader of the maglev industry and promote the green development of the cement industry!