24-hour customer service hotline:

0086+400-800-8605

+86176-1673-8512

Reservation:

+86-0536-7519229

Since the interview at the beginning of this century, high-speed maglev blower has been widely used because of its advantages such as high efficiency, high energy density, clean and oil-free, measurable and controllable. The maglev motor industry has achieved explosive development in the past 10 years.

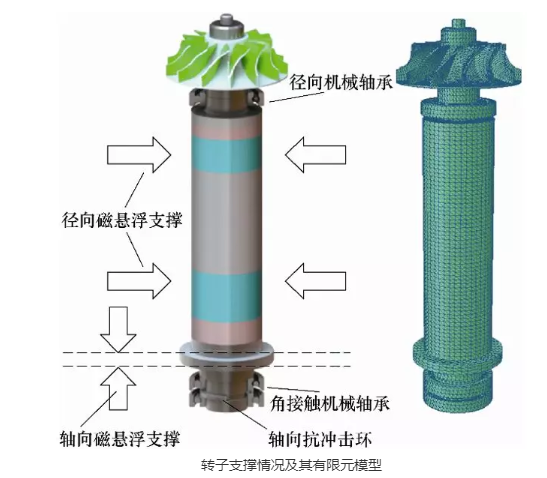

Due to the working mode of magnetic bearing support and high-speed direct drive, the high-speed magnetic levitation blower can significantly improve the working efficiency compared with the traditional blower, and has the advantages of cleaning, silence, low maintenance cost and no oil film lubrication. However, compared with the traditional blower, the high-speed magnetic levitation blower has special requirements for the locking device of the turbine blade.

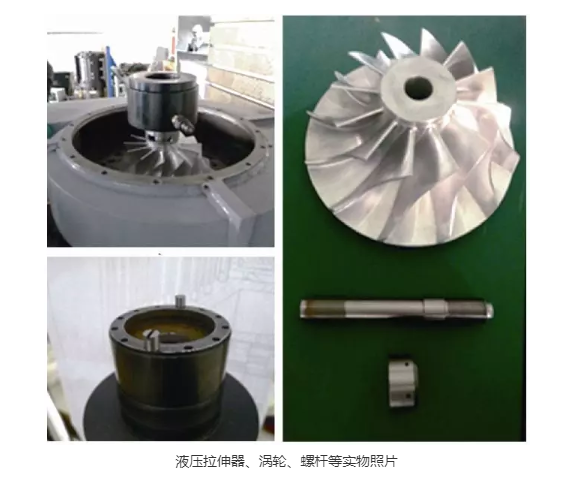

The article "design analysis and test of high speed magnetic suspension blower turbine locking device" puts forward a brand-new locking method of high power and high speed turbine, which is verified on a high speed magnetic suspension blower with rated power of 315 kW and rated speed of 30000 R / min. The experimental results show the effectiveness and feasibility of this method.

test method

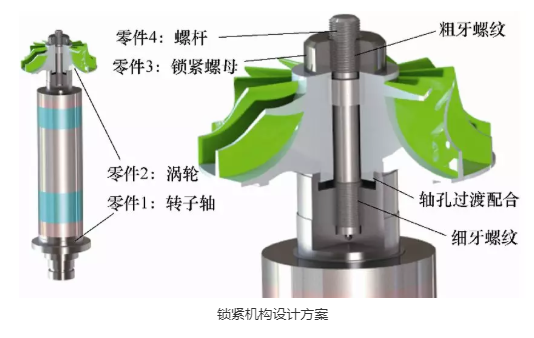

By analyzing the characteristics of the maglev blower, this paper points out the conditions that the turbine locking mechanism of the high-speed maglev blower needs to meet, that is, reliable locking, high strength of the turbine, high centering accuracy and detachability of the turbine. It is pointed out that the traditional installation method of blower turbine can only meet some of the requirements, but not all of them.

According to the requirements of the turbine locking mechanism of the high-speed maglev blower, we designed a new locking method of the high-speed turbine, and applied it to a high-speed maglev blower with a rated speed of 30000 R / min and a power of 315 kW. The specific process is as follows: firstly, the rotor is suspended by radial and axial full active magnetic bearings, and then the motor is accelerated and decelerated to see whether the impeller works stably. In a speed increase test, when the speed reached 4000 R / min, the magnetic bearing suddenly lost its stable suspension state due to disturbance, resulting in the rotor shaft falling onto the standby mechanical bearing at the speed of 4000 R / min. When the speed was increased again, it was found that the dynamic balance of the rotor was completely destroyed. After the machine was disassembled, it was found that the impeller was loose.

Through analysis, the problem that the anti impact load capacity of the original locking mechanism is weak is found. In view of this problem, the subsequent structure is improved. In the speed increase test after the improvement, the turbine has been working stably without looseness.

test result

The improved turbine locking mechanism of the high-speed maglev blower in this paper has been accelerated to 21000rpm in practical application, and it works stably without failure. The practical application proves the effectiveness of the structure.

Important conclusion

This paper presents the conditions that the locking mechanism of the high-speed maglev blower turbine needs to meet, that is, reliable locking, high strength of the turbine, high centering accuracy and detachability of the turbine.

The working principle and reliability of the turbine locking device are discussed based on the force analysis under four working conditions: acceleration process, steady speed operation process, deceleration process and accidental drop process.

Through the application test, the problem that the anti impact load capacity of the original locking mechanism is weak is found, and through the structural improvement, it can meet the effective locking of the high-speed maglev blower under all working conditions. The research in this paper can provide reference for the design and analysis of similar mechanisms.