24-hour customer service hotline:

0086+400-800-8605

+86176-1673-8512

Reservation:

+86-0536-7519229

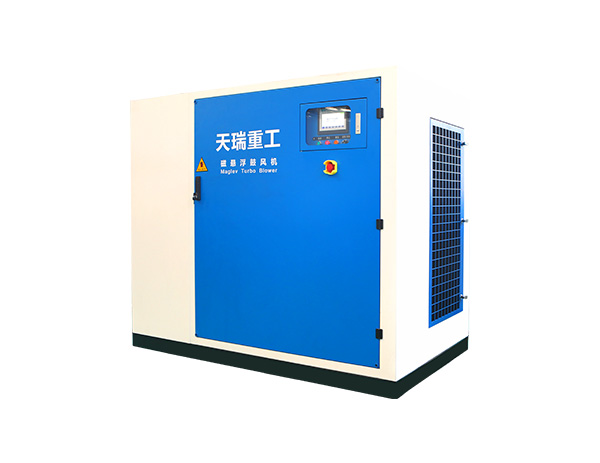

1、 Introduction to magnetic suspension blower

The maglev blower used by our factory is characterized by higher efficiency, obvious energy saving effect, low noise and stable operation than the general maglev blower. The Chinese touch screen is displayed in real time, which brings convenience to the operator and prevents accidents. The magnetic bearing is wear-free and does not need maintenance. It only needs to clean the filter. The cooling mode is air cooling, with good cooling effect. Due to the use of magnetic bearings, the air supplied does not contain grease and will not cause secondary pollution.

2、 Main functions of magnetic suspension fan

Aeration enters the sewage treatment system to increase the oxygen content in the water, so as to remove iron and manganese or promote aerobic microorganisms to degrade organic matters, so as to remove the oxidizable sediment.

In addition, aeration can make water and air fully contact, exchange gaseous substances, and remove volatile substances in water. For example, the odor of water can be removed, and harmful gases such as carbon dioxide and hydrogen sulfide can also be removed; The bottom sediment can also be inflated by the air at the inlet of the bottom air duct and discharged by the pump.

Third, correct operation methods and precautions.

Blower is one of the important process equipment in chemical wastewater treatment system. Proper operation of the fan can better prolong the service life of the fan.

Correct method to switch on and off the fan:

Turn on the fan: first click the green start button, then click the blue ready button, and then wait a few seconds.

"Power on the system" will display green, then click the small icon of the fan, and the fan can operate normally.

Turn off the fan: if you need to turn off the power, first click the fan icon in the touch screen to make it gray, and then click the red turn off button, otherwise the cooling fan will always be on.

4、 Fan cooling system

Fan cooling system is divided into internal cooling system and external cooling system.

Internal cooling system: air cooling is adopted, and the cooling fan reduces the internal coolant temperature. The internal coolant temperature throughout the design is maintained at approximately 40 ° C.

If air cooling cannot reduce the temperature of the coolant, external cooling water can be introduced to indirectly exchange energy with the internal coolant through the heat exchanger.

The coolant temperature of this figure is the internal coolant temperature. In winter, the cooling fan can take away the heat of the fan through the internal cooling system and the ambient temperature.

If you want to test whether the external cooling system is normal, there are two methods:

First, set the temperature of the coolant;

Step 2: turn the cooling water valve to manual and set the opening.

At this time, the external cooling system starts and water cooling starts. At the same time, the water will be discharged from the external cooling pipe.